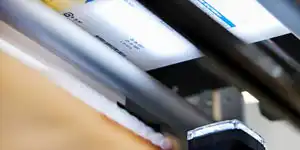

9410 Designed for medium to heavy duty production lines, Markem-Imaje 9410 CIJ printer reduces your TCO with quality codes.

Our continuous inkjet coder Markem-Imaje 9410 printers respond to most industrial needs, from black marking or color semi-pigmented solutions to inks for direct food contact.

-

product-test

Feb 5, 2025, 15:22 PM -

test2

Dec 5, 2024, 11:19 AM -

testtesttest

Dec 3, 2024, 16:12 PM -

SmartLase C600 X WIDE

Jul 10, 2023, 07:19 AM -

SmartLase C600 BOU

Jul 10, 2023, 07:18 AM -

9750 EXPERT SERIES

Jun 26, 2023, 07:57 AM -

9750 E SERIES

Mar 22, 2023, 08:34 AM -

9750 PLUS

Mar 21, 2023, 07:26 AM -

SmartLase C600

May 17, 2022, 05:31 AM -

9750

Apr 25, 2022, 07:19 AM -

SmartLase F250

Apr 8, 2022, 13:35 PM -

5940 G

Jan 18, 2022, 12:48 PM -

SmartDate OEM Connect

Nov 2, 2020, 08:40 AM -

SmartLase C340

Oct 20, 2020, 23:00 PM -

9410

Sep 22, 2020, 14:58 PM -

9330

Sep 11, 2020, 14:03 PM -

SmartDate X30

Jul 15, 2020, 16:17 PM -

CimPak

Jul 10, 2020, 14:11 PM -

2200 Pallet

Jul 10, 2020, 10:55 AM -

2200

Jul 10, 2020, 09:24 AM -

4700

Jun 10, 2020, 13:46 PM -

4500

Jun 10, 2020, 13:38 PM -

5800

Jun 9, 2020, 12:36 PM -

1200

Jun 8, 2020, 16:47 PM -

1050

Jun 8, 2020, 16:00 PM -

SmartLase C350 HD and HD Plus

May 27, 2020, 13:52 PM -

ES Series Fume Extractors

May 27, 2020, 12:58 PM -

SmartLase C350 BOU

May 26, 2020, 16:21 PM -

SmartLase C150 and C350

May 26, 2020, 15:56 PM -

SmartDate X65 128

Mar 11, 2020, 16:48 PM -

SmartDate X65

Mar 11, 2020, 16:12 PM -

SmartDate X45

Mar 10, 2020, 17:43 PM -

9450 S

Mar 9, 2020, 15:34 PM -

9450 E

Mar 9, 2020, 15:15 PM -

9450

Mar 9, 2020, 14:56 PM -

9029

Feb 12, 2020, 14:30 PM -

9018

Feb 6, 2020, 10:23 AM

DRAFT DRAFT DRAFT DRAFT DRAFT – draft draft

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

DRAFT DRAFT DRAFT DRAFT DRAFT – draft draft

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

DRAFT DRAFT DRAFT DRAFT DRAFT – draft draft

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

DRAFT DRAFT DRAFT DRAFT DRAFT – draft draft

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions